The jewelry sector is a special production area where micron-level precision and fine workmanship are at the forefront. Artech, with its CNC control systems and EtherCAT-based automation solutions developed specifically for this sector, emphasizes both detailed workmanship and efficiency in production. Engraving, carving and complex cutting processes are repeated, fast and error-free with Artech technology.

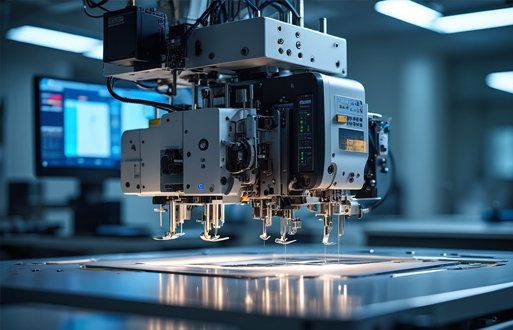

Artech's Codesys SoftMotion CNC solutions are designed for multi-axis processing systems used in jewelry production. It offers millisecond precision in milling, micro-cutting and engraving applications. Thanks to EtherCAT data bus integration, CNC machines operate synchronously, providing maximum compatibility and control.

Artech’s EtherCAT-based control systems stand out with their low latency and high bandwidth in jewelry applications. Micro-scale engraving, drilling and shaping processes are performed simultaneously and with high precision thanks to real-time data communication.

Artech CNC solutions, working integrated with servo motors and precision drive technologies, offer repeatability, speed and excellent surface quality in jewelry production. Thanks to these systems, an error-free and stable production process is provided even for high-value products.

Artech works fully integrated with CAD/CAM software and automatically converts jewelry designs into G-code. This eliminates the need for manual programming in production processes, minimizing the transition time from design to production.

Artech’s HMI solutions for jewelry applications offer a user-friendly and customizable interface. These .NET-based systems allow operators to easily monitor machines, make adjustments, and track data instantly. Uninterrupted communication is established between all systems with OPC integration. With SQL database support, process data is recorded and detailed reporting is provided.

EtherCAT and CNC-based systems developed by Artech are fully compatible with the Industry 4.0 ecosystem. It opens the doors to digital transformation in jewelry production by working integrated with IoT devices and cloud technologies. Thanks to features such as predictive maintenance, remote monitoring and data analytics, the production power of businesses becomes smarter and more sustainable.